Battery Packing

2022 - present

Purpose

The Battery Packing service initiative represents a landmark expansion of Giken Group's core capabilities—a strategic move designed to leverage its deep-rooted expertise in precision engineering and manufacturing. This initiative was established to deliberately and fundamentally position the Group at the epicenter of Southeast Asia's accelerating Light Electric Vehicle (LEV) market. This was not just an incremental expansion but a calculated move to secure the company's future by diversifying beyond traditional revenue streams, aligning with global sustainability trends, and decisively capturing the "China+1" supply chain opportunity demanded by regional Original Equipment Manufacturers (OEMs).

To realize this vision, the execution mandate was to build a fully integrated, regionally competitive manufacturing operation from the ground up. This required forging a new, powerful synergy between the Group's existing strengths and world-class capabilities in advanced cell-to-pack assembly processes. We established robust, in-house testing and quality assurance systems to ensure full digital traceability, and critically, cultivated the specialized talent needed to drive this high-tech venture. The ultimate goal was to deliver a comprehensive and scalable manufacturing solution capable of serving the rigorous demands of the global EV supply chain, evolving the Giken Group from a legacy manufacturer into a sustainable technology solutions provider.

Potential

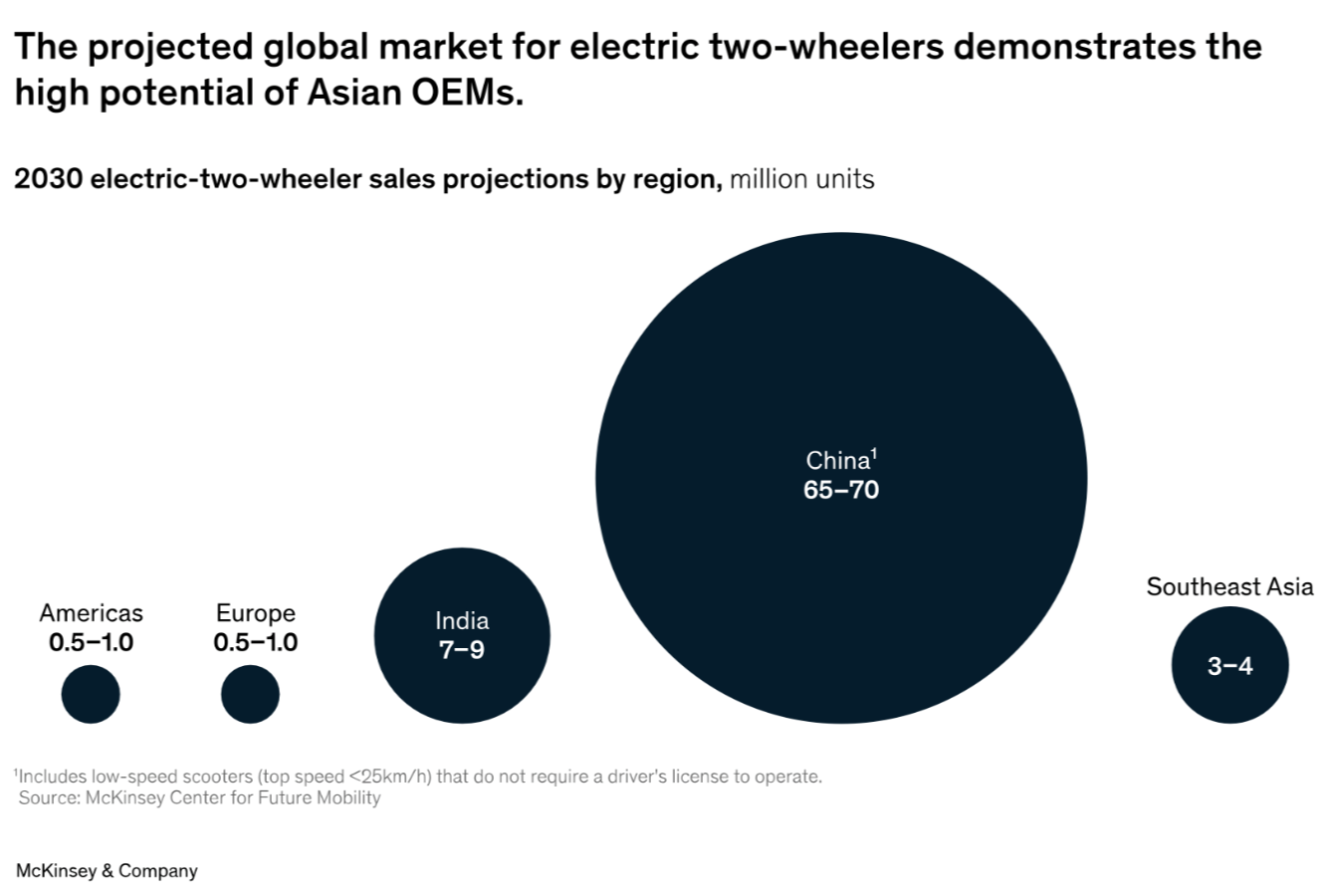

Southeast Asia is the 3rd largest market for 2- and 3- wheelers. This mobility landscape is on the verge of an electric revolution, and our initiative was timed to spearhead this change. Consider the fact that China and India have gotten to their inflection point for Light Electric Vehicles (LEVs), price parity has reached - SEA generally has a higher buying power than India. It is high time localization happens in SEA. Over the next five years, this market is projected to experience exponential growth, driven by government incentives for green technology, rising consumer awareness, and a pressing need for cleaner urban transportation. This created a clear and urgent demand for localized, high-quality battery manufacturing that could de-risk the supply chain for major OEMs. There is more nuance here, which I have to explain in a blog post. [PwC, McKinsey]

Our analysis identified a crucial market gap: the absence of a regional, OEM-grade battery pack assembly partner with the scale, discipline, and technical credibility to meet global standards. By establishing this capability in SEA, we positioned GRES not just as a supplier but as a strategic enabler of the entire regional EV ecosystem. We offered OEMs a secure, high-performance, and competitive alternative to sourcing from traditional manufacturing hubs, perfectly aligning our growth with the unstoppable momentum of the market itself.

Process

Velocity is a strategic weapon. Our execution philosophy was built on achieving maximum impact in minimum time. We successfully took the facility from an empty factory shell to a fully operational, TUV-audited production line in under six months. This was not an accident but the result of a fanatical commitment to disciplined execution and lean principles. Every decision, from facility layout to equipment procurement, was optimized for speed, efficiency, and scalability, allowing us to bypass the typical delays that plague complex industrial projects.

This rapid setup was achieved on a disciplined budget for the initial production line, post-factory M&E. We accomplished this by adopting a "zero-up" analysis for all capital expenditures, focusing investment on critical, value-adding automation while leveraging the Group's existing procurement and engineering strengths. This approach allowed us to build a state-of-the-art facility without the exorbitant costs, creating a lean operational model that provided an immediate competitive advantage on unit cost and served as a powerful proof point of our operational excellence to anchor customers.

Precaution

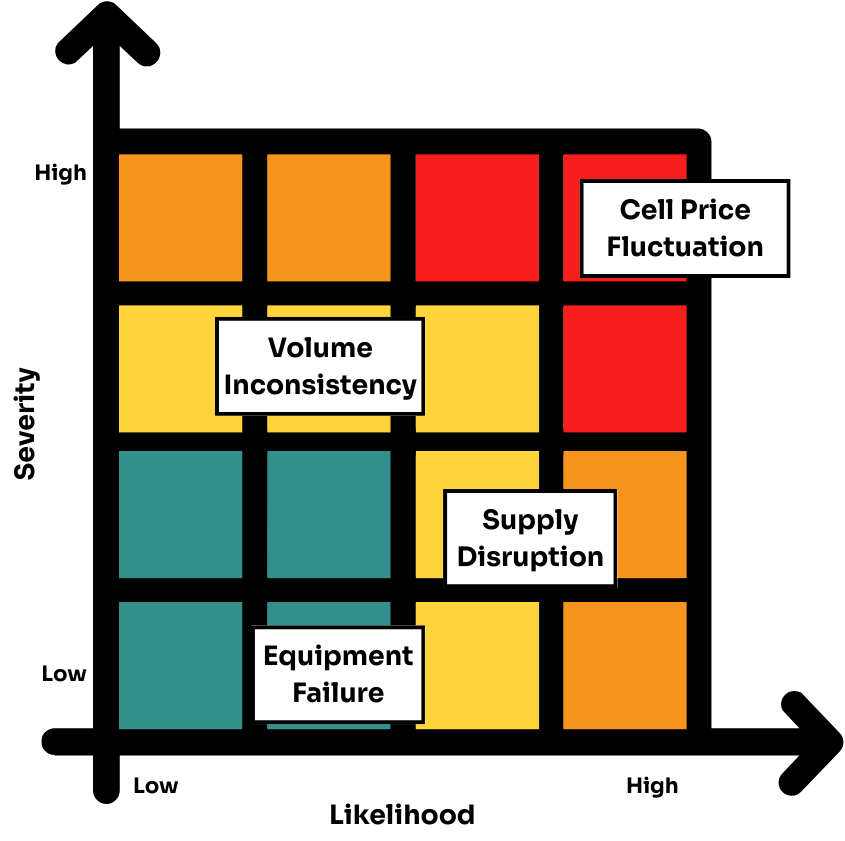

In a volatile market, foresight is paramount. We proactively identified and mitigated risks across the operational spectrum to ensure project integrity and build customer confidence. A primary Operational & Supply Chain Risk was the dependency on specific battery cell suppliers. Our mitigation was to engineer a cell-agnostic battery pack architecture and a flexible production line, giving us the agility to integrate cells from various top-tier suppliers without major re-tooling, thereby ensuring supply chain resilience.

On the factory floor, the Technical Risk was not in the product, but in the process. The challenge was maintaining impeccable quality and yield while scaling a complex, high-volume assembly line. We mitigated this by embedding a multi-layered quality assurance system directly into the production flow: rigorous incoming quality control (IQC) on all components, multiple in-line automated checks, and a accurate end-of-line (EOL) testing suite governed by our MES software. This created a digital shield around our process, guaranteeing full traceability and control from start to finish.

Performance

Our strategic execution translated directly into measurable, market-defining results. The performance of the initiative is best captured by three key milestones that validate our vision and capability.

Secured a Landmark 5-Year OEM Supply Contract. Before the line was even fully ramped, we secured a foundational, multi-year agreement with a major Taiwanese company, a global top-5 two-wheeler OEM. This was the ultimate validation of our strategy and execution, proving that our capabilities met the rigorous standards of a world-leading brand.

Achieved Unprecedented Operational Velocity. We set a new benchmark for industrial setup in the region by moving from a bare facility to a fully audited, mass-production-ready line in less than six months. This rapid deployment capability is now a core competitive advantage, allowing us to respond to market demand with unparalleled speed.

Scaled to a High-Volume Manufacturing Powerhouse. Within the first phase, we scaled the operation to a 350-person team in a 100,000 sq ft facility, achieving a validated production throughput of approximately 25,000 battery packs per month. This demonstrates our ability to not just build, but to scale with discipline and manage a large, high-performing manufacturing organization.